Document Type : Review Article

Authors

1 Department of Chemistry, University of Wah, Quaid Avenue, Wah Cantt., (47010), Punjab, Pakistan

2 Department of Physics, Division of Science and technology, University of Education, Lahore, Pakistan

Abstract

Several main energy conversion technologies need the improvement of extremely active, enduring, and economical catalysts for the cathodic oxygen reduction process. Some power conversion techniques including fuel cells and metal air batteries are efficient for the oxygen reduction process. The current improvements in platinum-based materials and platinum-free materials for fuel cell ORR catalysis are studied. Six primary types of contemporary ORR electrocatalysts are elaborated. Moreover, the efficiency of the resulting catalysts in respect of mass activity, kinetic current density, power density, and their inclusion into fuel cell processes, are also investigated. The benefits, drawbacks, performance of catalysts, and the need of rational design methods at the fuel-cell level are emphasized. Furthermore, the core issues, constraints, and possibilities are reviewed for developing inexpensive, more functional active, and stable electrocatalysts in the future.

Graphical Abstract

Keywords

Main Subjects

- Introduction

The atmosphere is really in great danger due to the rising global population and quickly increasing the efficient energy usage. Environment friendly and sustainable energy are more important solutions. Fuel cell technology and battery storage are commonly used for renewable energy sources [1, 2]. These are most auspicious approaches to the core combustion engines in automotive applications, and have the potential to reduce dependency on fossil fuels significantly [3]. The main fuel of a conventional polymer PEM fuel cell is hydrogen, which generates energy through water byproduct of its interaction with oxygen. ORR is used in fuel cell technology and battery storage [4]. In addition, the oxygen reduction reaction on the cathode of energy production strategies is a crucial process that lowers power transformation effectiveness [3]. The ORR becomes slow due to the huge over potential. It is a kinetically slow reaction (5 times than hydrogen oxidation process) that influences the total energy efficiency [5]. Therefore, finding electrocatalysts that can lower the ORR activated binding energy is critical for fuel cells to achieve appropriate efficiency [6]. On the one hand, ORR's kinetics demand a high concentration of valuable noble metal-containing catalysts like Platinum, which drives up the price of these electrochemical energy generation systems [7]. However, to increase the oxygen reduction process, efficient, and stable catalysts are required. Non-noble metal electrocatalysts, such as transition metal, nitrogen- carbon electrode materials, transition metal oxide, carbon materials, and MOF materials, have recently attracted the interest of researchers [5] that generalized classification is illustrated in Figure 1. However, because of their poor performance and stability in acidic PEMFC conditions, Pt-based catalysts retain their unrivalled advantages as an outstanding ORR catalyst. According to the report of the US Energy Department (2007) based on an estimated price of fuel cell manufacturing, the estimated cost for Pt-based catalysts accounts 56% of the fuel cell stack. As a result, the rate of platinum in the noble metal markets has a strong bearing on the price of fuel cells. Platinum's current premium pricing will almost certainly climb as demand for fuel cell energy systems grows. Therefore, the catalytic effectiveness of oxygen reduction electrode materials must be significantly modified to minimize or eliminate the need for noble Platinum [2]. Under corrosive working conditions, however, the long-term robustness of traditional ORR electrocatalysts remains a major roadblock [8]. In DOE-monitored test fleets, fuel cell cars used 0.4mgPt/cm2 or more on the cathode, yet catalyst stability fell short of the industrialization goal [5, 9]. The majority of current electrocatalyst research is focused on finding ways to save money and reduce price by decreasing platinum loadings on cathode while maintaining strength and reliability. Owing to the scarcity and expensive cost of Pt, reducing its quantity and improving its catalytic activity and stability has become a hot subject. Pt3Ni (111) had 90 times the activity of commercial platinum, which focused researchers' attention to Pt alloys [4]. The ORR activity of electrocatalysts based on both platinum and non-platinum group materials had been significantly improved. The high mass activity of 13.6 A/mg1Pt was achieved on ultra-thin sharp platinum-nanowires, when compared with commercial Platinum, which has a mass activity of 0.1-0.25 A/mg1Pt at 0.9 V [1].

Figure 1. Different types of ORR electrocatalyst

The creation of non-noble metal catalysts is single potential technique in power conversion technologies. An extensive range of non-platinum-based materials have been developed by utilizing various synthetic techniques. The oxygen reduction reaction efficiency and durability Non-platinum of the metal catalysts were previously much under the needed limits for use in polymer electrolyte membrane fuel cells. Non-platinum-based materials includes iron and cobalt double spots implanted in nitrogen-alloyed compact carbon, outperformed commercial Pt/C in acidic environments (0.1 M HClO4) [11]. Another way to decrease the Pt-loading is palladium based materials, because both have extremely comparable characteristics and are members of the same group. The oxygen reduction reaction activity of palladium is only slightly inferior to platinum, and it can be surpassed by adding an appropriate metal like cobalt or iron. In contrast, Pd's oxidation reduction reaction activity is considerably inferior than that of platinum, but it can be increased by adding a little quantity (5%) of platinum [12]. Metal-organic frameworks are a novel type of permeable material with high glass transition temperature achieved by strong interactions between metallic ions/clusters and organic ligands. MOF-based compounds have equivalent oxygen reduction reaction catalytic activities compared to commercial Platinum catalysts [13]. Heteroatoms like sulphur, phosphorous, and nitrogen doped carbons have been shown to be excellent oxygen reduction catalysts due to the interaction between the carbon and the electron density of the dopant atoms [14]. Single atom catalysts have sparked a lot of interest in the oxygen reduction process as a replacement for platinum based catalysts [1, 15].

Several studies have primarily focused on analyzing extremely effective ORR electro-catalysts that do not contain platinum or only contain trace amounts of this precious metal. In the last few decades, technology has made the significant progress in rationally designing and manufacturing superior platinum-based or platinum-free catalysts. When catalysts are reduced to nanoscale dimensions, they can exhibit appealing physical and chemical characteristics that are not seen in the bulk state. [16]. The information about the essence of the binding sites as a result of in situ characterization methods changes conventional evidence-based testing procedures to precise formulation and construction at the subatomic and molecular levels. Enhanced electrocatalytic activity may be gained by changing the atomic structure of the catalysts, particularly the surface electronic structure [5, 17].

This review focuses on new catalysts for more economical and viable corrosive PEM fuel cells, but it is not limited to that. Non-platinum group metal electrocatalysts are often unsustainable in acid media, but they exhibit good oxygen reduction reaction potency and stability in basic medium. After detailed description of ORR electrocatalysts, which are separated into different categories including precious or noble metal materials, palladium-based materials, non-precious metal materials, MOF-based materials, carbon-based metal, metal-free materials, and single-atom based materials. The ORR activity of the six categories of electrocatalyst is also slightly addressed and compared to that of Platinum-based catalysts. We examine TMO, TMN, TMC, and chalcogenides as non-noble electrocatalyst, meanwhile certain carbon-assisted materials and single atom catalysts are non-noble metal catalysts. During the study, we explore the difficulties and prospects of alternative electrocatalysts, with a focus on practical applications, which could aid in the creation of more appealing electrode materials for fuel cells and other sustainable power solutions [1, 18].

Figure 2. Reaction mechanism for oxygen reduction process in acidic and basic environment

1.1. Reaction Mechanism for Oxidation Reduction Process

Oxygen Reduction Reaction on Cathode

In Acidic Medium

In Alkaline Medium

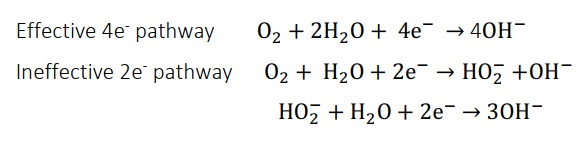

Atomic-level description of the oxygen reduction process is still in the beginning phases due to evident intricacy of Oxygen reduction reaction dynamics. However, total four linked proton and electron transports to oxygen at the cathode are known to be required for the overall electrochemical oxygen reduction reaction, as depicted in Figure 2 [1]. The ORR requires significantly more over-potential than the anodic hydrogen oxidation process. This is a multi-electron reaction that may contain many elementary stages involving distinct reaction intermediates at the same time [5]. The electro reduction of O2 can occur in different ways:

- Reduction of 4 electrons to water in acidic environment or hydroxyl in alkaline environment,

- 2-electron mechanism including hydrogen peroxide,

- A ‘‘series" of passage involving two and four e- reduction,

- A "parallel" system of channel involving processes (i) (ii), and (iii)

- An "interactive" pathway is feasible in which species spread from series to direct channel,

- The attachment of molecular oxygen and subsequent electron/proton transport to molecular oxygen and O2H (reactive oxygen species), which then break down into atmospheric oxygen and hydroxyl ion, is an associative operation.

A dissociative operation is one in which the molecular oxygen is broken, as well as the hydrogenation of atomic oxygen to hydroxyl and water [5, 17].

Although the selective reduction of oxygen to hydrogen peroxide includes the undesirable 2e- route, the 4e- pathway, (step 1 and 2) is the most viable reaction mechanism for ORR (step 3). Depending on whether the chemisorbed O2 breaks before or after protonation, stages 1 and 2 are referred to as dissociative and associative routes, respectively. The four-electron pathway should, theoretically, dominate the ORR process in the overall reduction of O2 to water (H2O) [19, 20]. The 2e- route, which involves incomplete oxygen reduction to H2O2 and is inescapable throughout the Oxygen reduction reaction, is believed to be related to a set of variables including imperfections, effective sites densities, and inter particulate spacing. However, with latest configuration, platinum-catalyst or non-precious metal catalysts, e is often minimal up to 2 percent. As a result, the following sections concentrate on the four-electron pathway [1].

The DFT simulations are frequently used to determine the free energy of intermediate compound. The principal oxygen transition products *O and *OH are implicated in both the dissociation and association pathways, with a supplemental *OOH for the others. As a result, the oxygen adsorption energy (DEO) should be investigated and used as an identifier for ORR performance. The ligand impact and the strain impact are thought to control DEO of PGM-based catalysts, whereas the locus of the d-band center compared with the Femi-level is thought to govern DEO of PGM-based catalysts. The scaling relationship among DEO and ORR has been well demonstrated in various tightly packed metal surfaces, such as "huge volcanic plots" with Pt placed throughout the optimum spot. A good target metal should have a moderate to high ability to bind oxygen. A poor contact will limit molecular oxygen adsorption and consequent breakdown to create O*, even though a strong connection will prohibit the removal of proton-coupled electron transfer intermediates (O* or OH*) [21]. Similarly "huge volcanic bends" have been created for platinum bimetallic alloys having DEO of roughly 0.2 electron volt, lower than pure platinum for the optimum model catalyst. DFT calculations are also widely used to identify patterns in catalytic activity for non-PGM ORR catalysts. Understanding and analyzing the patterns in ORR activity on different metal or carbon-based materials requires knowledge/relationships generated by experimental studies and DFT calculations, which gives vital direction for the creation of efficient ORR electro-catalysts [1, 22].

Figure 3. A schematic representation of a Fuel Cell

2. Fuel Cell

Fuel cells, like batteries, do not run out of energy and do not need to be recharged. As long as fuel is supplied, they generate hydroelectricity. Fuel cell is comprised of 2 electrodes that are a negatively anode and a positively cathode wrapped surrounding an electrolyte. The anode takes a fuel source, such as hydrogen or hydrogen carrier molecule, and the cathode takes oxygen called oxidant, as demonstrated in Figure 3. A fuel cell produces electricity by using the chemical energy of hydrogen or other fuels. Only electricity, water, and heat are produced when hydrogen is used as a fuel. Automotive, industrial, commercial, apartment blocks, and long-term grid power storage in reversible systems are the applications of fuel cell [24]. Fuel cells offer multiple benefits over conventional combustion-based technologies. Power devices can possibly be more productive than gas motors, changing the energy input into power with transformation efficiencies of up to 60%. When contrasted with ignition motors, energy units radiate less or no poisons. Since hydrogen power devices discharge water and no carbon dioxide, they can assist with settling significant environment issues. At the operative point, there are no air contaminants that cause smog or health issues [25].

Hydrogen Fuel Cells (FC) regardless of the fact that the great majority of past outstanding oxygen reduction electrocatalysts were only evaluated at the rotating disc electrode magnitude, there has recently been a significant trend toward emphasizing membrane electrode assembly testing for reported ORR electrocatalysts. The membrane electrode assembly comprises of a layer of impetus, gas dissemination layers, a proton exchange film, and exploratory investigations at the MEA level, is significantly more complicated than RDE tests. With the existing difficulties in mind, greater emphasis and effort should be placed into membrane electrode assembly magnitude and even fuel cell pile catalyst performance studies to consider and evaluate their promising applications in PEMFCs. In rotating disc electrode tests, many non-platinum based catalysts perform similarly to commercial platinum electrode materials, but in membrane electrode assembly tests, the specific density at 0.7 V and peak power density of carbon-assisted or single-atom oxygen reduction electrode material are quiet poor to Precious metal oxygen reduction catalysts. With a specific density of 1.0A/cm2 at 0.7 volts versus reversible hydrogen electrode and an overall platinum concentration of 0.39 mg/cm2 at both electrodes, the combination of basic platinum-cobalt nanoparticles with the cobalt doped nitrogen supported on carbon substrate resulted in highly active and stable electro-catalyst. Already, the simple solvothermal and subsequent leaching combination of grouped platinum-nickel composite nanocages was uncovered, which gave a current thickness of 1.1 A/cm2 at 0.7 V versus RHE while diminishing the general Pt content to 0.25 mg/cm2. A Pt-Ni nanocage power device impetus could create a current thickness of 1.5 A/cm2 at 0.6 V versus RHE and run for no less than 8 days. Alluring MEA execution was seen on numerous SAC-based impetuses. The manufacture of a wedge molded Fe-N-C SAC with suddenly high MEA movement because of its objectively planned open mathematical structure and expanded dynamic locales was revealed. The novel catalyst's specific density was 0.047 A/cm2 at 0.88 vs. reversible hydrogen electrode under the US Department of Energy testing procedures. In 2017, Ballard Power Grids revealed the first fuel cell system that did not use PGM-based catalysts, although the efficiency and kind of catalyst were not revealed. High-efficiency fuel cells based on non-precious metal catalysts are likely to hit market in near future, due to significant efforts from academics and industry [1].

3. Pt-Based Materials for ORR

The electrochemical process in cathodic ORR wants to be accelerated to acquire desired output due to its sluggish kinetics. So far, among all the catalyst available for ORR, platinum based electrode materials are the best one for its outstanding performance toward ORR (Figure 4). Due to this unique property, Pt-based catalyst are irreplaceable [26]. Beside the best performance of ORR, the major obstacle is the Pt price that is rising abruptly and rapidly and insufficiency of Pt. That’s why platinum is considered as industrial metal over precious metals [17]. According to an estimate by the US Energy department (DOE), the sky rocketing price of platinum bestow to about 41% of the total price of fuel cell stack. DOE has set a distinct goal to lower the amount of platinum to 0.125mgpt/cm2 for fuel cell. ORR is enough delicate to the surface electronic properties [26].

Figure 4. Pt-based materials for ORR

The efficiency and durability of Pt-based catalysts can be boosted by manipulating surface electronic properties. This process also increases the catalytic activity. The surface electronic properties can be controlled in four different ways: (i) Manipulating the visible facets of platinum and this result in maximum activity of platinum towards ORR, (ii) Fusing the platinum with the other metals to obtain multi-metallic alloys because bimetallic system shows high performance, stability, and durability as compared with single atoms, (iii) Introducing some foreign species by modifying the platinum catalyst surface such as organic compound and metal clusters, and (iv) Selecting such a catalyst which has high corrosion resistance. In this section, the recent advancement in platinum-based catalyst will be reviewed [6, 8, 17, 27, 28].

4. Shape-Controlled Catalyst

Platinum-based materials show 2 to 3 time’s higher activity than platinum. To enhance the system activity and performance of the fuel cell, the platinum loading should be reduced. When particles are reduced to nanoscale size, most of the physiochemical properties that aren't visible in the bulk form become visible, expanding the possibilities for making less price platinum based materials for fuel cell tenders. Shape-controlled platinum derived catalysts have ten times the mass activity and current density, as compared with commercially available platinum catalysts [27]. Shape controlled Pt-based catalyst are classified into polyhedra, Pt-nanocubes, Pt-nanoframes, and Pt- based nanowires.

Sides and border regions usually assist to the catalysts performance in nanomaterials with diameters less than 5nm. The ORR current density increases by a factor of four when the grain size is altered from 1.3 to 2.2 nanometers. The oxygen energy gap of platinum spots on cuboctahedral granules is assumed to be linked to these particle diameter-dependent properties. Because the fraction of border and corner spots drops as nanocrystals grow larger, there may be an "exchange" among both surface area and current density, resulting in a dimension-dependent peak value of overall efficiency for such electrocatalyst [16, 29].

Pt3Ni nanoctahedra was prepared by the reaction of platinum acetate, nickel acetate, oleylamine, and oleic acid in three neck flask under an organ stream in the presence of W(CO)5. Later on, it was revealed that W(CO)5 was responsible for Pt3Ni shape control. The Pt3Ni nanoctahedra yield was approximately 80%. Pt3Ni nanoctahedra were found to be stable and had an exterior surface separation outline compared with that of elongated Pt3Ni surfaces, according to Monte Carlo simulations. As a result, numerous researchers have reported high ORR activity after forming octahedral Pt3Ni particles, demonstrating that the strategic approach is able to solve catalyst problems [30]. Pt3Ni single crystal surfaces have a continuous rise in ORR activity over Pt and a 90-fold rise over the present condition of Pt/C catalysts. The prepared nanoctahedra Pt3Ni shows a boundless ORR mass activity of 2.67Amgpt-1. Glucosamine was used as a reductant, and chloroplatinic acid and nickel chloride were liquefied in deionized water with forcefully stirring in an airtight, PTFE-lined vessel to make Pt3Ni icosahedra nanocrystals. After 30 minutes the precursor solution was added in an autoclave at 180 °C for 6 hours. Later on, separation was done by centrifugation and scrubbing with deionized H2O, ethanol, and Pt3Ni icosahedra nano electrocatalyst was acquired. When contrasted to conventional platinum catalyst, Pt3Ni icosahedra nanostructures have 32 and 12 times boost in current and mass activities, correspondingly. Pt3Ni icosahedra nanocrystals, for example, have one of the highest ORR mass activity value is1.761 A/mg1 Pt and current density value is 6.38mA/cm2 Pt yet reported for energy storage applications [29].

Platinum acetate (Pt(acac)2), oleylamine, and oleic acid were used to make Pt3Ni nanocubes in a three-neck flask under an argon stream. Tungstun hexacabonyl W(CO)6 was introduced into the strenuously stirred solution. After that, a Ni-precursor standard solutions was made by dissolving NiCl2·6H2O in a mixture of solvents comprising oleylamine and oleic acid. The temperature was gradually increased from 130 to 240 °C and stock solution was added drop wise. The yield of Pt3Ni nanocubes was approximated to be around 70%. Without W(CO)6 Pt3Ni nanocubes can also be prepared but their shape is less controlled. It is clear that the ORR activity is reliant on the particle shape and the composition. As prepared Pt3Ni nanocubes shows a mass activity of 0.62 Amgpt-1. The same procedure used to make Pt3Ni nanocubes was used to make platinum nanocubes, except for the Ni precursor absence [26]. Because of their reasonably large effective surface area platinum atom consumption, Pt-based nanoframes have emerged as among the most efficient and long-lasting ORR catalysts in the last two years. Pt-based nanoframes were created by folding two atomic layers of platinum into 3D Pt3Ni nanoframes, which exhibited unexpectedly high activity, stability, and reliability during the redox reaction. Pt3Ni nanoframe catalysts have a unique design that allows for a better utilization of platinum atoms on the surface due to their open 3D porous structure (Figure 5). It is widely recognized that pt-based nanoframes catalysts have a higher durability and stability due to their highly uniform crystal surfaces because nonfunctional sites on the nanoparticle surface are simpler to dissolve. Furthermore, because of the standardized homogeneous composition, big particles become bigger and fine particle shrink in size, reducing the Ostwald ripening procedure. Therefore, the Pt-based nanoframe is one of the most favorable, durable, and highly stable catalysts. The 3D Pt-based nanoframes imparted a diverse number of effective spots on both the interior and external surfaces, making the oxygen reduction process easier and boosting the electrocatalyst's overall effectiveness. The precise development of the frame structure and morphology in Pt-based nanoframe catalysts is a significant challenge. The slightly elevated facet has recently been discovered to be responsible for such outstanding results [31].

Nanowires and nanotubes are 1-dimensional nanostructures based on Platinum monocrystal nanostructures that develop along a definite path of a lattice nucleus. These Pt-based nanostructures can reduce the inserted points at the electrode-catalyst interface, allowing the catalyst to perform at its full potential. For the time being, a smaller number of particle junctions can improve electron transmission. Because of the excellent electronic transmission and dispersion of Platinum nanoparticles, 1D Pt-based nanowires and nanotubes have shown a better ORR activity. Nanowires and nanotubes with high-index substrates were created to improve ORR activity. Huang et al. created a unique 3-dimensional strand of Pt–Co nanowires with well-proportioned high-index aspects. This research revealed the most practical and efficient method for maximizing platinum atom consumption in poly-metallic nanowires with large surface areas. Huang et al. also revealed that the mass activity of prepared Pt3Ni Nanowires was 3.96 A/mgPt1. Pt-based nanowires and nanotubes can be incredibly reliable, with almost no noticeable loss after multiple potential periods in RDE. The stability and durability of Pt-based 1D nanowires and nanotubes have been demonstrated, but high index facets on the surface of nanoparticles cause instability and make control difficult. If the facets of Pt-based NWs and NTs change, the ORR activity decreases [4].

Figure 5. Mass activity of different Pt-based shape controlled catalyst

5. Pt-Based Alloys

Platinum has been reported to be alloyed with various elements, including vanadium, chromium, titanium, manganese, iron, cobalt, nickel, tungsten, molybdenum, iridium, palladium, and zinc. Using potentio dynamic RRDE measurements, a rise in ORR activity of alloy catalyst was observed as compared with the pure Pt of 1.5 to 5 times. It was also discovered that the ORR on a Pt alloy catalyst has a 20-40 millivolts lower over potential than solo Pt [32]. Platinum group metal alloys have been attaining the maximum electrochemical stability, as compared with Platinum. The Pt3Ni exterior is preferred for its strong mass action against ORR. The fraction of accessible platinum exterior employing cuboids and other prismatic crystals was found to boost oxidation reduction catalytic efficiency and durability for Pt3Ni nanocrystals. The measured ORR activity enhancement in Pt alloy electrocatalyst is mostly due to a change in platinum’s interface electronic characteristics, which results in higher in Oxygen reduction performance in Platinum alloy electrocatalyst [9].

Poly-crystalline hybrid layers of platinum and metals catalysts (metal may be nickel, cobalt, iron, and titanium) were made to investigate the influence of 3d metals on the catalytic ORR efficiency of Platinum alloys. It was observed that the strong ORR efficiency of these platinum blends is attributable to 3d transition metals. The d band center and the catalytic performance of platinum blends are demonstrated to have a key relation. The optimum catalytic efficiency was directed by an equilibrium between absorption coefficient of energies of reactive species and the outer layer covered by spectator species, which resembled a volcano [32]. The Pt-alloys, which are the best Oxygen reduction electrocatalysts, attach oxygen molecules weaker than pure platinum and have the highest ORR activity. The most appropriate alloying elements are nickel, cobalt, and iron. In both ORR current density and mass activity, the volcano type behavior of electro catalytic activity was exposed, which was dependent on the type of 3d metal ion. Bimetallic Platinum based electrode material for ORR has formerly been thoroughly explored [17, 31, 33]. Bimetallic platinum-cobalt Pt3Co is one of the most potent bimetallic catalysts (Figure 6). After witnessing the highest ORR catalytic efficiency and stability of a bimetallic catalyst, we hypothesized that by introducing gold or iridium to a Platinum 3d bimetallic system could affect the oxygen reduction catalytic performance. We achieved adjustment knob of the oxygen reduction reaction electrocatalytic efficiency towards the volcanic apex after inserting gold, suggesting that the ternary catalyst platinum-gold-cobalt blends exterior binds oxygen weakly than platinum but somewhat higher than platinum-cobalt. The ternary composite catalyst Pt-Au-Co has a current density of 1.41 mA.cm-2 at 0.9 Volts, which is much higher than the binary alloy catalyst Pt3Co. Substituting Iron for the binary alloy catalyst, platinum-cobalt does not result in desirable Oxygen reduction electrocatalytic efficiency. Following 100,000 potential loops, Pt-Au-Co shows a 25% drop in the current density, while binary alloy catalysts show an 80% loss in specific activity. After 100,000 loops, the current density of Pt–Au–Co is 140 percent higher than that of platinum-cobalt [34].

Figure 6. ORR activity of Pt-based multimetallic catalyst

6. Surface Modified Pt-Based Materials

Aside from regulating the exterior faces of platinum nanomaterials and combining platinum with certain additional metals to create binary alloy nanostructures, ternary nanostructures in the form of composites, and core–shells strands. Platinum electronic properties can be improved by adding metals complexes, molecular species, carbonaceous, and inorganic component to the outer surface of platinum nanocrystals, which is beneficial to the ORR activity. The ORR catalytic performance was improved in surface modified Pt-based materials, which was dependent on covalent and non-covalent interactions on the platinum electro-active facets for ORR. In an intense adsorptive H2SO4 solution, molecular sorption of melamine over Pt[111] surface resulting [Pt{111}–Mad], the Oxygen reduction efficiency can be increased massively when matched to bare Pt[111]. Although the ORR is unobstructed, the sorption of melamine on the platinum surface specifically obstructs the sorption of bisulfate ions, resulting in the toxicity of the Pt[111] surface. Compared with cyanide species adsorbed on the Pt[111] exterior, the melamine-based Pt-surface 111 has better chemical stability. In a H2SO4 environment, Pt[III]-Melaminead has a nine fold higher ORR efficiency than pure Pt[III]. The greater consistency of the Pt[111]–Melaminead edges is attributed to melamine capacity to establish intermolecular hydrogen bonds, which effectively transform melamine components into bigger supramolecular bodies with countless attaching spots, making them more difficult to remove [35].

Carbon assisted platinum and platinum-metal (Metal: iron, cobalt, and chromium) hybrid catalysts are made by using the poylol reduction technique. In this method, metal components were simultaneously reduced and broken down with 1, 2-dihydroxyhexadecane in the presence of Pelargonic and nonylamine safeguarding reagents. According to Xiaong et al., who used a reduced-temperature reduction procedure with HCOONa to synthesize multiple carbon-assisted platinum-metals electrocatalysts, the platinum-cobalt electrocatalyst had the best results, with the highest catalytic properties and the least polarity when compared with traditional Platinum catalyst (Figure 7). The catalytic ORR activity of platinum bimetallic alloys containing cobalt, iron, and nickel created by vapor deposition was examined, with highest activity found at 40, 50, and 30%, respectively. The maximum increase in dynamic flux density was 20 times that of bare platinum. At both low and high current densities, carbon-assisted platinum-metal (cobalt, iron, and chromium) catalyst produced by the poylol reduction process outperformed conventional platinum catalysts with moderate polarization losses. In addition, the constant current voltage of carbon-assisted platinum-Iron, platinum-cobalt, and platinum-chromium electrocatalysts is 0.53, 0.59, and 0.61 Volts, respectively, which is higher than that of as-prepared and traditional platinum catalysts. The power density rises as the cathode material is detected, from platinum 7 to 10 mW/cm2 to platinum-metals alloys, which were 16, 20, and 21 mW/cm2 for platinum-iron, platinum-cobalt, and platinum-chromium electrocatalysts respectively (Figure 8), and this improvement would be due to alloying effect and supported on the carbon surface. Pt alloys had 1.5 times the ORR and a lesser voltage across a potential of 50 mV than commercial Pt/C catalysts, according to electrical and chemical studies [32].

Figure 7. Specific activity of Pt-supported materials

Figure 8. Power density showed by different Pt-supported ORR catalyst

7. Pt-Free Catalysts

The slow kinetics of the ORR and the increasing costs of platinum catalysts, are stifling the quick growth of fuel cells. Therefore, it is quite interesting to avoid Pt-based catalyst and explore the new advanced and cheaper non-platinum electrocatalyst for ORR process in fuel cells that will result in improved ORR activity. Many studies have been published to cut the price of Pt by lowering Pt amount by tuning the electronic surface of platinum, which is used to make binary and ternary alloys, introducing foreign species, and manipulating Pt's exposed faces. Further Pt-free catalytic materials lead to the significant cost reductions. In this section, our emphasis is on development of Pt-free less expensive materials that are accountable for achieving the maximum oxygen reduction efficiency and material stability that is closed to the Pt catalyst. Pt-free less expensive materials includes the cheaper Noble metals (Pd, Ir, Ru, and Ag), cheaper non-noble metals(Cu), non-precious metal catalyst (M-N-C, MOx,, MNX, and MC), metal organic frameworks based materials, and carbon-based materials [5, 17, 18].

8. Palladium-Based Catalyst

Alternative options to platinum include palladium, iridium, ruthenium, gold, and silver derived catalysts. Palladium and silver have received much interest in comparison to those other heterogeneous catalyst because of their greater oxygen reduction activity, reliability, enormous amount, and low price. Due to much less cost of Pd., fuel cell manufacturer switched from Pt-based catalysts to palladium based catalyst. Palladium and platinum belongs to same group in and have comparable properties. Pd shows very close activity to ORR and exhibit lesser over potential for ORR [17]. It is possible to improve the catalytic efficiency of Pd-catalysts by altering their electronic properties [5]. Adding exotic species to palladium is one way to change the electrical properties of the metal. Several palladium metals (iron and cobalt) bimetallic are being cast-off as oxygen reduction catalysts in recent years to improve Pd's ORR electrocatalytic performance and stability. It has been proposed that the active metals in Pd-M alloys operate as a place for O2 bond splitting, resulting in adsorbed oxygen that transfers to porous areas guided with Palladium. There are many structures like Cu-Pd, Mo-Pd, and Co-Pd are similar in activity to Pt in catalyzing the ORR [12].

Bimetallic alloy Pd-cobalt was examined for Oxygen reduction efficiency with a diversity of palladium and cobalt atomic proportions, and resulted in the maximum catalytic performance equivalent to Platinum. It was also discovered that as the degree of alloying increases in Pd: Co with a molar ratio of 70: 30, the ORR performance decreases. Contrarily, the maximum ORR activity was achieved in Pd-Co catalysts due to the maximum Co content in alloy and minimum Pd-Pd interatomic distance. Due to presence of the maximum amount of Co, particle size of metal decreases and surface area of prepared catalyst increases. This results in maximum stability and durability of Co-Pd catalyst. The specimen treated at 350 °C demonstrated a good balance of maximum catalytic stability and efficiency for ORR at cathode. The ORR performance of a ternary Pd-Co supported electrocatalyst was also investigated. Gold (Au) was added to binary Pd-Co electrocatalyst. The ORR performance of the ternary prepared Pd-Co-Au electrocatalyst is higher than that of the commercially prepared platinum catalyst. Another ternary Pd-based catalyst was created by mixing Mo into Pd-Co motivator. The result was ternary Pd-Co-Mo, which had better ORR catalytic activity than commercial platinum catalyst and stable performance than previously prepared Pd-Co-Au (Table 1) [12, 36].

Another Pd-Fe catalyst was studied with different Fe ratios. The oxygen reduction efficiency of prepared several bimetallic palladium-iron was studied. Compared with conventional platinum, this resultant bimetallic Pd-Fe with atomic ratio of 3% had the highest oxidation reaction efficiency and improved catalytic stability. Other binary catalysts of Pd was studied extensively in acidic medium like Pd-Cu, Pd-Cr, Pd-Ni, Pd-S, and Pd-W. Except for Pd-S, all of these catalysts have the highest ORR catalytic performance in contrast to platinum and nearly equivalent stability to pure palladium [37].

Table 1. Activity of different Pd-based catalyst in different medium

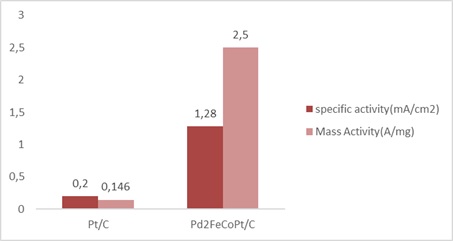

Facet engineering resulted in the creation of Pd-supported ORR catalysts, which will greatly improve ORR activity and durability. The ORR performance on Pd single crystals has been monitored in the past, and the results show a pattern opposite than that of platinum, namely Pd(100) ‹ Pd(111) ‹ Pd(110), suggesting that the Oxygen reduction surface region on the Pd (100) side is perhaps the most effective. The catalyst particle size and superficial strain should be controlled through manipulating the surface chemistry and optimize catalytic efficiency. We present a Pd-based catalyst in which the superficial strain of the Palladium nanocatalyst could be changed to improve its ORR efficiency in fuel cells by incorporating both iron and cobalt into the palladium lattice. Pt is also added to the synthesized Pd-based catalyst Pd2CoFe/C, resulting in increased mass activity of 38 and 11.25 fold that of commercial platinum in 0.1M HCLO4 and KOH solutions at 0.9V (Figures 9 and 10). Adding Pt to a Pd-based catalyst improved the ORR performance [38].

Figure 9. Power density of Pd-based catalyst compared with Commercial Pt

Figure 10. Mass activity and specific activity of Pd-supported catalyst compared with Pt/C

Another palladium based material Pd-Fe (Figure 11) bimetallic catalyst supported on carbon with different ratios of Fe (1:1, 2:1, and 3:1) was synthesized without adding any stabilizing agents. As a result, carbon-based palladium and bimetallic catalysts Pd-Fe have been developed with excellent ORR specificity and efficiency that is similar to commercial platinum Pt/C. These catalysts were made at ambient temperature with no thermal treatment [18].

Figure 11. Tafel slope, mass activity, and specific activity of palladium-based materials compared with Pt/C in A and B

The third way is modifying Pd's electrical properties to locate suitable support systems that can boost palladium and palladium-supported electrode material sensitivity by allowing efficient electron bonding among both palladium and the assisted material. Pd–W18O49 is a type of composite nanomaterial that is made up of a palladium tetrahedron and tungsten oxide nanostructures. The result was surprising, reported hybrid nanomaterial (Pd–W18O49) exhibits extra-ordinary catalytic ORR activity and shows a higher activity to Pt in alkaline medium. Pd nanoparticles show a less catalytic activity toward ORR. The Pd alloys and its ORR activity are presented in Table 2. It was reported that the maximum catalytic activity and durability of Pd nanoparticles toward ORR is due to Pd-O bond [18].

9. Cupper-Based Materials

Due to its abundance on the globe, copper has been intensively explored in a wide range of domains, particularly glass electrodes and organo-catalyzed reactions. As in processes of glycolysis, H2O2 reduction, and methanol oxidation, Cu-based nanomaterials have proven to be excellent electrocatalysts. The early experiments originally reported the ORR parameters for a substantial copper electrode [39]. It was claimed that a one-pot technique was used to manufacture subnanometer-sized copper aggregates with high ORR oxygen reduction reaction performance. The catalytic performance of copper clusters is also affected by the characteristic size of their cores. Cu3N nanocuboids with a mean diameter of roughly 11 nanometer were made by using a simple one-pot procedure that could be adjusted by changing the amphiphillic molecules. Electrochemical experiments demonstrated that the as synthesized Cu3N nanocubes had good catalytic activity for ORR in basic conditions. Though pristine copper oxides can catalyze the ORR reaction, they have limited electrochemical applicability due to their low electrical conductivity. Numerous investigations have shown that using graphene as a support optimizes the electrochemical behavior of copper oxides. Despite the fact that the Cu2S nanoplates did not shows the great ORR activity as compared to the commercial platinum catalyst [39,40].

We illustrate a set of copper-palladium hybrids and copper-palladium nanostructured on huge active surface area graphite hybrids that can be used as efficient catalysts in energy technologies such as fuel cells. In an antacidic environment, all of the composites showed considerable ORR electrocatalytic performance. With starting voltage of 0.84 V and 0.91 V and charge density of -3.5 and -4.2 mA/cm2 at 0.3 V, the Palladium-high surface area graphite and copper-palladium-high surface area graphite composites had the best results (Figure 12) [40].

Figure 12. ORR activity of Cu-based catalyst is compared with Pd-based Catalyst

Table 2. ORR activity of different Pd-Alloys in fuel cell [41-52]

Figure 13. Non-precious metal catalysts for ORR

10. Non-Precious Metal Catalyst

Impetuses that accelerate the oxidation of fuel at anode and the reduction of oxidant at cathode separately are the primary prerequisite for more extensive utilization of power modules to make power. For PEM power modules, platinum, which was initially utilized by William Grove in 1839, is right now the main viable impetus [7]. Platinum is one of the most expensive to emulate metal in the world. It is not achievable to furnish a huge number of vehicles with platinum-based power devices from a monetary and natural angle. One solution is to use non-precious metal catalysts instead of Pt-based catalysts at the oxygen-reduction cathode, which would lessen the Pt content by a significant margin [53]. There are numerous ways to minimize Pt loading in cathodes without compromising their performance: Boosting the mass efficiency of platinum for oxygen reduction process through adding different metals or core-shell nano structuring, improving the mass-transport characteristics of platinum cathodes, and growing elite execution nonprecious metal impetuses for oxygen reduction process are largely considerable needs [11]. We depict a group of non-valuable metal impetuses that can coordinate with the viability of platinum derived frameworks at a lesser expense, making them reasonable for high energy unit present day auto power. The non-valuable metal electrocatalysts for oxygen reduction process incorporate non-pyrolyzed and carbon supported metal nitrogen compounds, transition metal chalcogenides, nitrides, carbides and perovskites (Figure 13) [10,54,55].

11. Transition Metal Nitrogen Carbon

Because of their minimal price, large catalytic activity, consistency, and resistance to the methanol cross-over impact, transition metal nitrogen carbon composites are the most attractive options among non-valuable metal ORR catalysts, and found that M–N–C has ORR catalytic activity and durability are nearly equivalent to commercially available Pt/C catalysts. Transition metal nitrogen carbon composites are effective for two reasons: (i) The performance of ORR is entirely dependent on nitrogen properties on the exterior of carbon supported catalysts and (ii) Nitrogen properties on the exterior of carbon-derived accelerators are mainly accountable for ORR performance, and nitrogen-groups serve as just a collaborating setting for iron and cobalt ions in which the ORR process takes place [56]. Transition metal macrocycle compounds have really been exploited for a multitude of scenarios, especially as an electrocatalyst in a various processes. A chelating ligand N4 in combination with a non-precious metal was reported as a feasible alternative for electrochemical reduction of oxygen. ORR activity has been investigated in a variety of macrocyclic ligands with transition metal, including porphyrin and phthalocyanine. In each of these complexes, the Noble metal atom is uniformly enclosed by N4. The electron transfer from the electron donating core material to the diatomic oxygen p* orbital is expected to weaken the O-O bond, causing O2 to be halved. In spite of the new distribution of a promising framework with 1.01 Volts open-circuit voltage and power thickness of 0.33 W/cm2 greatest voltage at 0.2 MPa outright strain at 808, the effectiveness of fuel cells dependent on these materials. [53].

Transition-metal with nitrogen and carbon must all be contemporary at the same time to optiFmize ORR activity, according to the overall direction. We recently published a study focusing on materials obtained without heat treatment at first to synthesize non-valuable metal electrocatalysts of the high oxygen reduction catalytic performance and strong reliability and consistency. At the elevated temperature production of iron and cobalt catalysts, polyaniline (PANi) is used as a co-substrate to a carbon-nitrogen framework. Only PANI-derived compositions show the strong oxygen reduction catalytic performance with distinct efficiency and robustness in high-temperature non-valuable metal electrocatalysts. They demonstrated impressive ORR performance in a bitter environment with a E1/2 capability of 0.79 V, only 60milivolts variance from commercial platinum, greater sensitivity and specificity, and superior electrochemical stability. For the PANi supported metal-nitrogen-carbon composites, DFT calculations were used to ensure that the catalytic activities drop significantly in the sequential manner Co–PANI < Fe–PANI< CoFe–PANI. This is because of CoFe–PANI, a synergistic impact between heterogeneous metal atoms allows for more charged particle donation from active sites to adsorbed reduced oxygen dimers. As a result, these non-noble catalysts still have a hard way to go in order of ORR catalytic stability and activity. Non-platinum oxygen reduction electrocatalysts with high methanol endurance, such as iron-nitrogen supported carbon and cobalt supported carbon, are expected to be good choices for tackling the cost problem of fuel cell electrocatalysts, despite of extended kinetic energy of fuel cell commercialization. Iron-nitrogen supported carbon and cobalt supported carbon have lesser catalytic performance than Pt-based catalysts [3].

A set of non-valuable metal impetuses with iron, cobalt, or manganese as the transition metal and a reinforcing material of N-changed active carbon are produced using the following stages (Figure 14): (i) Topping of an N-rich polymer on activated carbons, (ii) Impregnation of the matching metal porphyrin on the N-polymer/activated carbon composite, (iii) Thermal decomposition at 800C in an inert atmosphere, and (iv) Dissolution of metals by means of acid to detach non-stable phases dramatic weight decline of iron-nitrogen supported carbon, cobalt-nitrogen supported carbon and manganese-nitrogen supported carbon specimens that recovered after step (ii) as the temperature inside the nitrogen surrounding was extended [57].

Figure 14. Steps involved in synthesis of non-valuable metal catalyst

Figure 14. Steps involved in synthesis of non-valuable metal catalyst

The effectiveness of all of the catalysts in terms of ORR in acid medium was assessed by means of electrochemical methods. At typical capabilities between 900 and 700 mV, the catalytic efficiency follows the iron > Cobalt > Manganese trend in terms of oxygen reduction process beginning voltage and high specific density. Apart from all the type of transition metal, the amount of nitrogen and iron integrated into the carbon polymeric network reduces the thermal decomposition treatment, which leads to the production of genuine catalyst active surface area for the ORR. The NPMCs only show strong and stable electrocatalytic effectiveness for the oxygen reduction process after the carbonization phase. This process, which is likely aided by graphitic-N species, results in the creation of more ORR effective surface sites. To make pretty active ORR electrocatalyst, the transition metal must be carefully chosen. According to our results, iron produces more efficient electrode materials than cobalt and manganese for the oxygen reduction process. In this study, ortho, meta, para-phenylenediamine/iron/carbon forerunner is used to make iron-based ORR catalysts through thermal treatment approach [58].

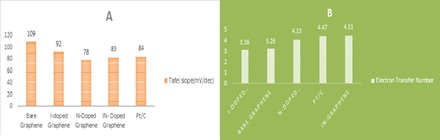

A facile heat treatment using iron salt, graphitic carbon nitride (gC3N4) as precursors, and chemically whittled down graphene yields iron-nitrogen-functionalized graphene (FeNG) as a NPMCs. When comparing the electrocatalytic performance of the synthesized catalysts to that of Sequential scanning cyclic voltametric tests on pristine graphene sheets show that the iron-nitrogen-functionalized graphene catalyst has a higher positive beginning potential and greater reduction specific densities, indicating that FeNG catalyst has a better ORR activity than pristine graphene. The FeNG, in particular, has the maximum peak power thickness of 1150 mW/m2, which is 2.1 times significantly greater than the commercial platinum (561.1 mW/ m2) and considerably higher than the Pristine Graphene (109 mW/m2). These findings suggest that in practical MFC applications, the FeNG catalyst could be a fine replacement for the more expensive platinum catalyst [59,60].

Figure 15. Power density of iron functionalized nitrogen supported on carbon compared with Pt/C

Nanosized Mn(III) oxide was used to make a thin layer counterpart. The bifunctional oxygen reduction performance and activity of this plentiful and reduced price catalyst is equivalent to the best renowned precious metal catalysts like platinum, ruthenium, and iridium [61]. In an alkaline exchange membrane, catalyst like this could be used as the oxygen cathode where oxidation reduction reaction takes place. A simple process for preparing thin layer like cobalt-nitrogen-graphene composites (Co-N-G) has been reported that function like an extremely active and potent NPMCs for the oxygen reduction reaction. Polypyrrole/graphene oxide (PPy/GO) nanostructures have been prepared at room temperature through in-situ polymerization. Cobalt (II) nitrate as a precursor was then heat treated instantly into the PPy/GO blends to create the Co–N–G composites. The cobalt-Nitrogen-Graphene nanocomposites had exceptional electrocatalytic activity toward ORR, equivalent to commercial platinum, with greater onset potential, remarkable tolerance to the presence of methanol, and absolutely superb alkaline environment consistency. They were consider as the modern and more explored non-precious metal (NPM) ORR electrocatalysts for electrochemical applications because of these properties [62].

12. Transition Metaloxides (TMOx)

Because of their outstanding stability and catalytic efficacy, transition metal components such as TMOs have been widely studied as ORR catalysts in alkali environments. TMOs (transition metal oxides) are a material family that has sparked a lot of interest in the research community for ORR. These mixtures are comprised of change metal oxides from the d-block, which may be single or blended metal types [63]. TMOs are appropriate to electrocatalytic purposes since they might show a wide scope of valence states and glasslike stages that can be changed or altered to maximize effective site association with the ORR items [64]. The minimum cost TMOs are easier to acquire and control than other transition metal compounds that increase their demand. On the other hand, TMOs have also some downfalls. Transition metal oxides are semiconductors, they must be made more conductive before they can be used as electrocatalysts. Previously, TMOs have been found to be very effective when combined with different outstanding conductive precursors, including nanomaterials, carbon-supported materials, and highly conductive polymers. Because of their varied oxidation states and high electrical conductivity, metal oxide from d-block metals are promising aspirants for non-platinum oxygen reduction electrocatalysts [63]. CoOs have been lauded as one of the most encouraging electrocatalysts for power device processes when contrasted with other transition metal oxides. It is modest, high surface-to-volume proportion with synthetically stable situations, and higher explicit potential make it appropriate for energy-related gadgets (890 mAhg-1). Co3O4 has precious stone construction and possess tetrahedral and octahedral opportunities, separately for Co2+ and Co3+. A crossover material comprised of Co3O4, 3D nitrogen-functionalized graphene nanofillers and nanocrystalline, named Co3O4/N-GAs, was integrated to test ORR. The catalyst was made by using the low-cost precursors and a one-pot hydrothermal technique. The reaction is clearly carried out in a four-electron reaction mechanism with a greater current density and a long lifespan. TMOs with a variety of exposed facets were also successfully synthesized. The forms of nanorods, nanocubes, and nanooctahedrons with different exterior surfaces 110, 100, and 111 were reported previously. The performance sequence of ORR nanocrystalline is Co3O4 ‹ Co3O4 –NR ‹ Co3O4 –OC indicating that the catalytic performance of the Co3O4 111 surface was the highest among all others [62].

ORR electrocatalysts have also been discovered in TMOs such as titanium oxide, niobium oxide, and tantalum oxide [64]. In recent years, another category of oxides, the perovskite oxides with the general formula ABO3, has attracted a lot of attention. Perovskite materials with metals at effective B- site are substitute electrocatalysts for reduction of oxygen to water only through the ORR activity [65]. Essential cations like La3+ are found in the transition metal oxides with the perovskite structure; oxides of these particles are unsound in solid corrosive arrangements. Therefore, basic arrangement has been utilized to investigate perovskite metallic oxides as permeable cathodes. ORR activity could be influenced by the number of transition metal d-electrons, the robustness of the M–OH bond, and its impact on rate-determining processes involving intermediates [7, 17, 66]. However, insufficient knowledge about ORR reaction mechanism and the material characteristics that influence electrocatalytic activity still exists. (La,Sr)A(Ni,Mn)B(Ni,Ru)B′ O6 (LSNMR), a dual perovskite with particular cationic species in the A, B, and B′ positions, has been reported. The contrast among the potential estimated at 1 mA/cm2 for the ORR has a striking bifunctional record of 0.83V. In basic medium, this bifunctional LSNMR electrocatalyst has phenomenal ORR and OER performance. The 0.94V ORR beginning potential is one of the most amazing so far for ORR-dynamic perovskites in antacid conditions. The oxygen reduction mass action of LSNMR is 1.1A/g1 at 0.9V and 7.3A/g1 at 0.8V. Density functional theory interpretations showed that the maximum ORR performance of LSNMR is linked to the existence of effective Mn positions due to the strong symmetry of the respective reaction mechanism on those position [67]. In addition, the catalyst is relatively durable during Oxygen reduction cycling. Another perovskite oxide based on Ba, Sr, Co, Fe, and O (BSCF5582) is being praised a di-functional electrocatalyst candidate for oxygen reduction process and oxygen evolution process [66].

Copper oxides and cobalt oxides are good non-valuable metal electrocatalysts for oxygen reduction process because of their large specific surface to volume ratio, varied valence states, and chemical inertness. Still, due to its low conductivity and catalytic activity, it is not suitable for broad use. To improve CuOx's electrocatalytic capabilities, mixing it with carbonaceous material is a viable option [68]. It was reported that Cu2+ ions have a stronger tendency for forming stable complexes with N-based ligands. CuO and N-rGO are therefore combined to form a nanocomposite, CuO/N-rGO, with high ORR activity. With a 4 electron transfer throughout the reaction, this nanocomposite may rapidly decrease HOO- intermediate, leading in a high current density and a higher positive start potential [60, 69]. Catalysts made of manganese oxides (MnOx) are another potential type of cathodic material for alkaline fuel cells. They are cheap, plentiful, and safe for the environment, and they come in variety of shapes and sizes, several of them have been reported to have significant electrocatalytic performance for the 4e- lessening of oxygen. Carbon electrodes, the most common substrate for oxygen reduction facilitators in fuel cell cathodes, have long been acknowledged as catalysts with high inherent action for the electrical reduction of oxygen to peroxide. In this way MnOx is supported on carbon electrodes. We report the ORR activity of bare graphene and graphene supported MnOx electrodes in air as a function of thermal treatment over a range of temperature. In our experiments, Mn3O4 was discovered to be a MnOx phase with 4e- reduction of oxygen for the ORR performance and an approximated specific density of 3700A/cm2 at 0.75V vs. [RHE], a value that is incredibly fierce with the effective precious and nonprecious electrocatalysts for the oxygen reduction process in core. A simple technique was used to make another Mn2O3/LiNi1/3Co1/3Mn1/3O2 composite electrocatalyst. Hybrid electrode catalyst are synthesized having a high porosity and a large surface to volume ratio. The hybrid electrode catalyst has an extraordinary capacity for oxygen sorption. The NCM-2 (Mn2O3/LiNi1/3Co1/3Mn1/3O2) composite material has outstanding electrocatalytic properties for oxygen reduction process, as well as improved stability. As Oxygen reduction triggers, a new class of transition metal oxides called CoxOy, MnxOy, FexOy, and others is gaining traction [70].

Iron is an inexpensive, abundant metal with greater ORR selectivity, making it a viable substitute for precious metal catalysts. Iron is thought to be particularly effective and energetic in ORR activities. Due to their reduced oxygen reduction action, iron oxides, on the other hand, have a limited universal applicability in fuel cell technology. During their amalgamation, uncontrolled development and accumulation happen, bringing about a misfortune in execution. A decent method for conquering these deterrents is to use a conductive help, and carbonized materials. ORR is effectively catalyzed by the created nano-Fe3O4/graphene composite. The improved properties are said to be due to the beneficial synergistic bonding impacts among both iron oxide and graphene [71].

Another material for ORR in energy-related applications is metal oxide porous frameworks, which have a greater surface area, light weight, and the maximum loading potential. Transition metal oxides with porous frameworks, which act as oxygen-related catalysts, have a low over potential, a fast reaction rate, and high stability. Templating procedures make it simple to create hollow structures. It was reported that ZnCo2O4@NiCo2O4 core–sheath nanowires with a hierarchical structure have also been produced uncontrollable an amalgamation of easy electrospinning and a simple co-precipitation method. The onset potential of the hierarchical structure is analogous to that of conventional platinum catalyst, but it is far more stable. It is hierarchical core sheath architectures improve reactivity and ion transport significantly. For Fe-based spinels, porous CoFe2O4 nanostructures with a distinguishable bimodal microporous structure were described. This 3D hierarchical hollow structure is beneficial for oxygen transport and the development of a three-phase reactive action interface in metal–air batteries. As a result, there will be a higher ORR activity and an improvement in stability [72]. A wide range of highly effective modern catalysts have been produced by dumping massive volumes of transition metal oxides like manganese oxide, cobalt oxide, nickel oxide, copper oxide and iron oxide onto nitrogen-doped carbon nanotubes for di-functional catalysis in basic medium. The metal oxides were distributed onto functionalized CNTs using an enhanced impregnation technique. This new method allows for the production of di-functional nitrogen-doped CNTs and a uniform distribution of MOx on the CNT wall surfaces. The 50wt% MnO2-CNT catalyst is the most effective ORR electrocatalyst in this series, with a E1/2 prospect of 0.84V at a specific density of -2.1 mAcm-2 and a beginning voltage at 0.98V vs reversible hydrogen electrode [72-74].

As oxygen decrease impetuses, we gathered cobalt porphyrins and d-metal oxides on gold and carbon or graphene cathodes. After porphyrins were momentarily impregnated, d-metal oxides like cobalt oxides and nickel oxides were set utilizing either unconstrained or electrochemical accumulation techniques. The oxygen reduction activity results show that co-deposited d-metal oxides increases the movement of cobalt porphyrin towards oxygen reduction process. The CoOxCoP/Au impetus was more dynamic in working with oxygen reduction than the NiOxCoP/Au impetus [75].

Figure 16. Structure of (A) porphyrin (B) cobalt porphyrin (C) 2-methylimidazole (carbon building block for ZIFs)

Figure 16. Structure of (A) porphyrin (B) cobalt porphyrin (C) 2-methylimidazole (carbon building block for ZIFs)

13. Transition Metal Chalcogenides

Over the last period, d-block metal chalcogenides M–X, where metal is cobalt, ruthenium, rhenium, rhodium, and X is sulphur, selenium, or telenium have been studied as the ORR electrocatalyst. Baresel et al. explored the cathodic oxygen reduction response on chalcogenides of d-block metals in 1974 and found that the cobalt-Sulphur and cobalt-nickel-sulfur frameworks had the most noteworthy electrocatalytic execution, with 2250 mA/m2 or 1000 mA/g1 at 70 and beginning capability of 600 mV in 2M H2SO4 electrolyte, individually. At the point when the distinction in energy between the 2p orbital of oxygen and the most populated d-orbital of the metal of the sulfide diminishes, the action in the relating intensifies drops in the order of sulphur > selenium > telenium [76,77].

The early transition metal chalcogenides electrode material have been proposed as possible non-platinum oxygen reduction electrocatalysts due to the advantages of less price, powerful ORR efficiency, excellent methanol resistance, and ease of fabrication. Hydrothermal/solvothermal soft synthesis, only one forerunner soft synthesis, one-pot synthesis, template assisted synthesis, and Kirkendall effect are the most commonly used early transition metal chalcogenides methods. Cobalt sulphides have been studied as the most active Oxygen reduction electrocatalyst among the chalcogenides acidic solution. Through a 4e-ORR pathway, the electrocatalytic efficiency of Co9S8 is assumed to be similar to the platinum, and S-S offers a sorption position for Oxygen after O2 bond cleavage. For ORR, a ternary effective composite Co9S8–N–C catalyst was synthesized in alkaline medium. The ORR activity of Co9S8–nitrogen supported on carbon catalysts is much sophisticated than that modern platinum catalyst in 0.1M NaOH solution [76]. This study designed a new trinal non-vluable metal chalcogenide, rest on tungsten and cobalt in an effort to increase ORR electrocatalytic activity. While these two non-precious metals are sluggish against the ORR and unbalanced in a sharp solution, electronic characteristics changed by a chalcogen atom such as selenium are predicted to expand their constancy and efficiency. In an acidic environment, the ORR catalytic efficiency, constancy and durability of the synthesized ternary tungsten-cobalt-selenium chalcogenide was assessed. The link among the altered electronic characteristics and the electrocatalytic efficiency was investigated which shows an effective ORR electrocatalytic efficiency [77]. Another significant class of chalcogenides is u-based chalcogenides.

14. Transition Metal Carbide and Nitride

The d-block metal nitrides with elevated electrocatalytic efficiency, stability, and enduring robustness are also hunted by oxygen reduction electrocatalysts. To make carbon-assisted Co-N, the reflux and temperature treatment were used. It is equivalent to traditional platinum catalyst in terms of catalytic efficiency, but it overtakes Platinum in terms of stability. Zirconium oxynitride and tantalum oxynitride were discovered to have a reasonable ORR performance and outstanding chemical resistance in sulphuric acid. The commutative properties of Molybdenum nitride and dimolybdenum nitrides were demonstrated.[78]. To make a complex catalyst, dual d-block metal nitride nanoparticulates titanium-cobalt-nitride were placed on nitrogen-incapacitated reduced graphene oxide. The electrocatalysts demonstrated the excellent oxygen reduction activity in an antacid media. The maximum E1/2 capacity of the Ti-Co-Np/N-rGO catalyst was 0.902 V against RHE which was 30 mV significantly high than the marketing Pt/C catalyst, and the output specific density was 2.51mA/cm2 at 0.9V against RHE. The oxygen reduction action of d-block metal nitride-nitrogen doped-reduced graphene oxide was essentially advanced than that of metal nitride or N doped reduced graphene oxide alone showing a huge synergic movement between the two materials. The ORR activity was excellent, and the reaction went through a roughly 4e-cycle [79]. Nanosized ZrN was produced using the urea glass approach technique, and the ORR efficiency was established to be sophisticated than that of the conventional platinum catalyst. The ZrN nanostructures were also found to have an extraordinary efficiency analogous to that of the modren commercial Pt catalyst [67].

Cobalt-tungstum supported on carbon matrix treated with active NH3 was found to be structurally oxynitride. By looking at the strong correlation among both specific density and innumerable nitrogen-holding classes, they discovered that d-block metal nitrides and pyrrolic nitrogen both seem to be effective agents for the ORR catalysis. It was found that cobalt-molybednum oxynitride, is preferable in the ORR catalytic reactions in basic environment because of high beginning voltage 0.918V against reversible hydrogen electrode and reasonable in acidic environment. The metal carbides with electrical properties and consistency in acidic conditions had been previously used as electrocatalyst support systems for ORR by adjusting the d-band center to the ideal location, with tungsten carbides being the most commonly used. They have now established themselves as ORR catalysts. Molybdenum is one more metal whose carbide has electronic characteristics compared with platinum, resulting in a synergetic action amongst the Platinum catalyst and the molybdenum carbide backing. The microwave-assisted technique was used to successfully produce well-dispersed Mo2C particles of 3 nanometer size on the surface of carbon nanotubes. The efficiency of the conventional platinum over molybdenum carbide support on carbon nanotubes revealed a high electrochemical effective surface area to volume ratio and a greater oxygen reduction beginning voltage. ZrCN, TaCN, and NbCN are metal carbo-nitrides with strong oxygen reduction efficiency, principally after half-done oxidation, with ORR onset potentials of 0.97, 0.9, and 0.89 V, respectively [78].

15. MOFs-Based Materials

Metal-organic frameworks based catalyst (Figure 17), comprising pure metal organic frameworks, their composites, and associated parent materials, are appearing as distinctive electrode materials for ORR activity in the perspective of alternative sustainable sources of energy [13]. MOF derived electrocatalysts offer unique possibilities to speed up the slow oxygen reduction process at the cathode surface in energy storage devices such as fuel cells due to their changeable compositional content and morphologies. The precious metal catalysts are recognized as the excellent ORR electrocatalysts with 4e- route (Figure 18). Unfortunately, because of its shortage, high cost, and poor robustness, platinum is not extensively employed in renewable energy systems. Given these limitations, developing earth-copious, high efficiency, and long-lasting alternatives is indeed a necessary but tough task [80]. Metal-organic networks are a new form of porous structure with excellent crystallinity and broad range ordering that are linked by coordinate covalent bonds between metallic ions and organic connectors [81].

Figure 17. ORR activity of MOF’s based materials

Depending on the chemical makeup, MOFs derived electrocatalysts are grouped into three types: crystal-clear metal organic frameworks, MOFs based composite materials, and their analogues [30]. Metal organic frameworks with porous channels and accessible sites with redox ability may have a greater active site usage than traditional heterogeneous catalysts. However, their electrocatalytic uses are severely limited because of inadequate electrical conductivity and chemical stability [30, 81]. Metal organic frameworks can be combined with novel functional nanomaterials such nano-carbon based materials and nanostructured materials (nanoparticles) to obtain excellent electrocatalytic performance [31, 82]. Another simple and practical way is to use immediate calcination or indirectly post-treatments to convert metal organic framework materials or MOFs-hybrids to inorganic hybrid materials [83]. Because of their structural and compositional advantages, MOF derivatives often have a huge surface area, outstanding electrical permeability, and excellent chemical inertness [80, 81, 84]. This mini-section starts with an explanation of ORR and Metal organic frameworks, and then divides MOFs-based electrode materials into categories depending on their ORR potential. In constructing MOF-derived oxygen reduction process electrocatalysts, the importance of synthesis technique, composition, shape, geometry, electrocatalytic effectiveness, and reaction conditions is addressed. Non-noble metal-centered electrocatalyst, specifically iron and cobalt centered catalysts have already been investigated for the effective ORR electrocatalysis because precious metals like Pt, Ir, and Ru are in short supply and expensive. The ORR performance has previously been observed in MOF-based carbon materials with atomic scale distributed metal sites, metal based nanostructured materials, and composite based nanoparticles, all of which have been discussed in this section.

Figure 18. ORR mechanism in MOFs based Materials

The zeolitic imidazole frameworks, or ZIFs, are one of the more well-studied MOF groups due to their structural resemblance to zeolites, a family of aluminosilicate minerals. 2- methylimidazole is a typical carbon building block for ZIFs, with a structure similar to that illustrated in Figure 16 (C). When zinc is doped into the MOF, it becomes ZIF-8; when cobalt is doped into the MOF, it becomes ZIF-7 [85].

To replace Pt-based materials, non- precious metal based catalyst with greater and optimum ORR are desperately needed. The metallic cobalt and nitrogen co-doped carbon based catalyst were produced by using a standard thermal decomposition technique, and alloy of two metals zinc and cobalt based ZIF was created by using polypyrrole and polyaniline copolymers as precursors. The acquired MOFs composite electrocatalyst ZIF-ppy-pani-750 has a greater ORR efficiency than bare ZIF-750 (Table 3), which is similar to the previously described conventional platinum electrocatalyst and other ORR electrocatalysts (Figure 19) [86].

Table 3. ORR activity of MOF-based catalyst and commercial Platinum catalyst

Figure 19. Comparison of ORR activity between MOFs and Pt/C

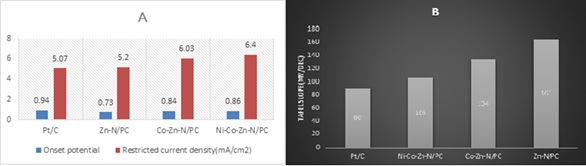

By using a one-pot approach, we demonstrate how to produce hollow carbon catalysts doped with nitrogen, cobalt, zinc, and nickel. The effective metal components are combined with 2-methylimidazole to create a zinc centered zeolitic imidazolate framework with nickel and cobalt as a dopants for the formation of nickel, zinc, cobalt, and nitrogen multi-doped porous carbon via thermal annealing, in which compartments and pores are formed naturally to zinc volatilization at extreme temperatures. In particular, as-synthesized nickel cobalt zinc and nitrogen multi-doped porous carbon exhibits advantageous ORR electrocatalysis at 0.864 V half-wave voltage and restricted oxygen reduction current density of 6.40mA/cm2, outstanding resistance to methanol and enhanced long-term consistency. Metal air batteries especially Zn-air batteries of nickel, cobalt, zinc, and nitrogen multi doped porous carbon as the cathode material also has an extremely high open circuit voltage, high detection limit, power density and reliability, indicating that it could be useful in real energy conversion devices. However, in the sequence zinc and nitrogen doped porous carbon (5.20 mA/cm2, 0.736 V) < Cobalt-zinc-nitrogen doped porous carbon (6.03 mA/cm2, 0.848 V) < Nickel-zinc-cobalt, and nitrogen multi-doped porous carbon (6.40 mA/cm2, 0.864 V), the limiting current density (JL), and E1/2 increases, indicating that ORR efficiency of highly porous nanocarbon catalysts improves as doped metal elements starts rising (Figure 20). Tafel slope has long been recognized for its importance in revealing reaction mechanisms, particularly in elucidating rate-determining stages. The nickel, zinc, cobalt, and nitrogen multi-doped porous carbon has the smallest Tafel slope (90 mV/dec1) that is comparable to that of commercial platinum, revealing that nickel, zinc, cobalt, and nitrogen multi-doped porous carbon has higher efficiency and stability than the other two microporous carbon catalysts [87].

Figure 20. Onset potential, current density of different MOFs materials are compared in A and Tafel slope in B

The cobalt p-phenylenediamine coordination compound was created by using p-phenylenediamine as an organic binder, and it was then examined further as a novel ORR electrocatalysis. p-phenylenediamine with multiple amino groups was chosen as an organic binder to bind with cobalt and form a coordination compound cobalt p-phenylenediamine due to the high inclination of its -NH2 molecule to interact with inorganic cationic species. Cobalt p-phenylenediamine compound had bisecting nanolayers and resembled a flower after a simple hydrothermal treatment. Even more, the patterning of the matched products was totally retained after decomposition at extreme temperature and acid etching in 0.5 M H2SO4. In contrast to other approaches, by using p-phenylenediamine as the only nitrogen and carbon organic binder has the clear advantage of being cheap, easy to make, and appropriate for large manufacturing exhibiting great repeatability. The novel cobalt and nitrogen doped carbon electrocatalyst has the potential to be a worthy substitute for platinum electrocatalysts due to its high electrocatalytic efficiency and impenetrability (Figure 21) [22].

Figure 21. ORR activity of a MOFs based Co@NPC

Phosphorus, a group of heteroatom like nitrogen with chemical properties compared with nitrogen has diverted the attention. Because of the difference in diameter and electronegativity, phosphorus-doping of graphene sheets differs significantly from N-doping [88]. Phosphorous-doping of carbonaceous material has better electron-donating properties, great O2 adsorbent, and strong oxidizing agent than the N atom, indicating that it is a feasible ORR electrocatalyst. Even so, in carbon Phosphorous-doping, no agreement exists on the reaction sites. Mesoporous carbon supported materials with heteroatom dopants have subsequently gained considerable attention because of its remarkable catalytic efficiency for an oxygen reduction process. MOFs are anticipated to improve ORR cyclic stability and catalytic performance by forming noble metals like iron and cobalt doped with a substituent like phosphorous and nitrogen. We present a bunch of new iron and cobalt integrated in phosphorous-doped porous carbon materials with excellent ORR efficiency using an in-situ combustion technique. The electrocatalytic efficiency and stability was evaluated by the combustion temperatures and quantities of the two metals. Iron and cobalt integrated in a phosphorous doped moderately permeable sample burned at 9000 oC offers the highest electrocatalytic strength and endurance because of the combined impact of the two noble metals. Cobalt and iron integrated in Phosphorous doped extremely microporous materials appear attractive as electrode materials to replace platinum catalysts in energy storage devices like fuel cell, according to electrochemical testing. The FCPA-900 sample, which was directly analogous to the commercial platinum catalyst, had the highest electrochemical performance of the three samples. FCPA-900 is a possible future electrocatalyst for fuel cells that could replace Pt-based catalysts (Table 4) [88,91,92].

Table 4. ORR activity of FCPA at different temperature and compared with commercial platinum catalyst

We made a MOF-74 substrate with different metals species of iron and manganese and a cheap organic reagent dihydroxybenzoic acid, which we then bonded with melamine and heated up at 800oC under noble gas flow rate to make fundamental electrocatalysts. Iron and manganese bimetallic nanoparticles are encapsulated in nitrogen doped carbon nanotubes in all of these electrocatalysts. With an electron transfer total count of 3.95, Fe3Mn1/N-CNTs-100 outperforms Pt/C catalyst in terms of ORR strength as well as consistency, implying a 4e-transfer mechanism. Fe3Mn1/NCNTs-100 has the best ORR effectiveness, outperforming Pt/C catalyst, with a positive E1/2 of 0.865 V and a jk of 1.447mAcm2 at 0.9V onset potential (0.855 V, 0.946 mAcm2) [93].

Figure 22. ORR activity of bimetallic iron and manganese based MOF-74